Precision

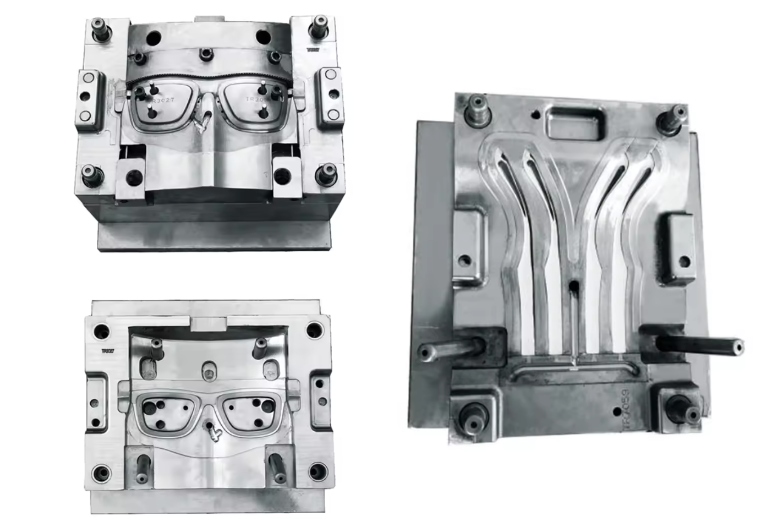

Strict tolerance control ensures every frame faithfully matches the original design intent.

Precision

Strict tolerance control ensures every frame faithfully matches the original design intent.

Durability

High-performance tool steels and optimized machining processes extend mold life and maintain long-term stability.

Repeatability

Whether producing 500 pieces or 500,000, results remain consistent.

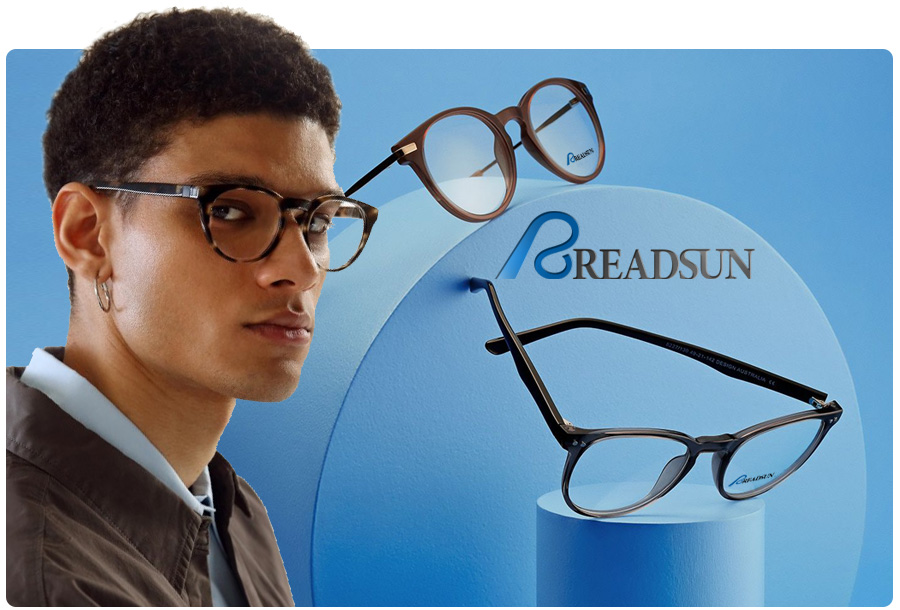

The origin of every frame.This stage defines the product’s DNA — style, ergonomics, dimensions, aesthetics, and brand identity.

Experienced engineers create detailed 3D models to visualize the mold structure and predict final frame performance.

Rapid prototyping allows early validation of dimensions, form, and visual appeal before final mold production.

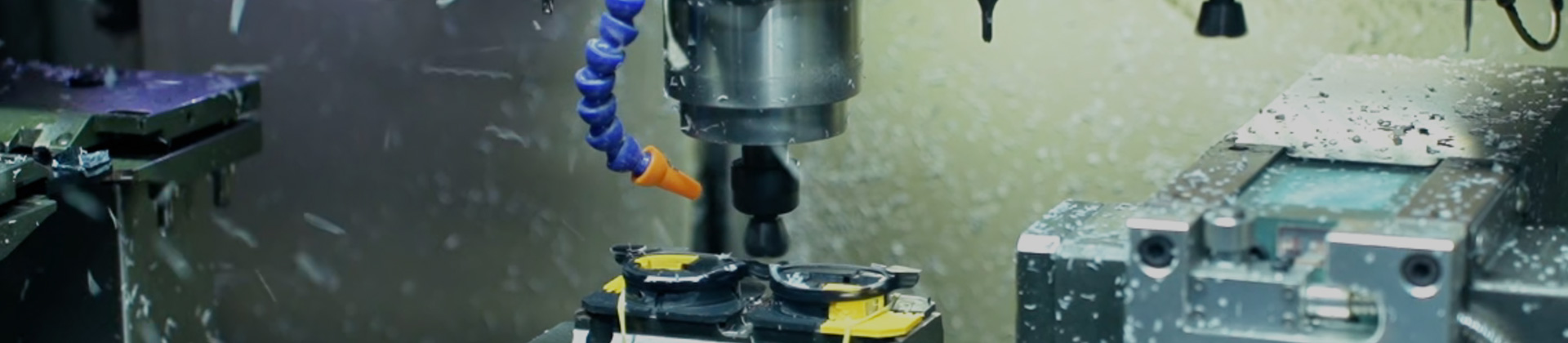

Precision CNC machines manufacture molds using premium steel or specialized alloys.

Each mold is tested for dimensional accuracy, repeatability, and surface quality before full-scale production.

Premium tool steel, aluminum alloys, or special alloys ensure durability, dimensional stability, and superior surface finish.

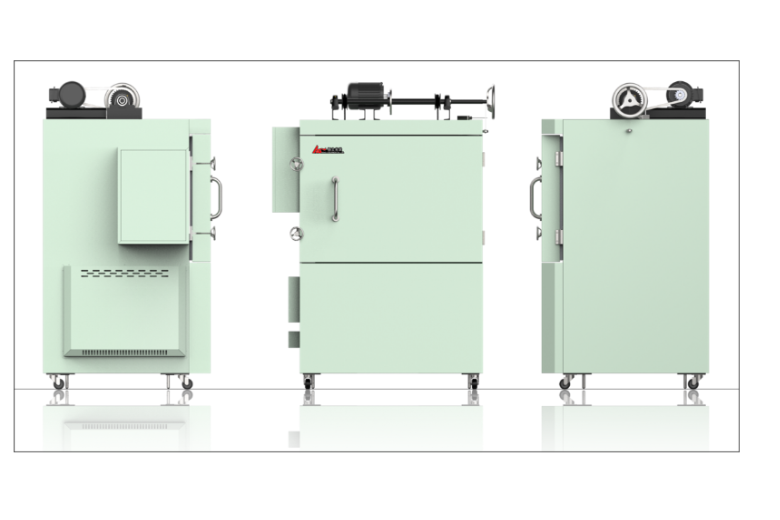

Advanced machines maintain tight tolerances and production consistency.

Carefully polished mold surfaces prevent defects and enhance frame appearance.

Defines precision, efficiency, and manufacturing complexity.

Advanced equipment directly influences detail accuracy, surface finish, production stability, consistency, and unit cost — delivering fewer defects, faster cycles, and superior results.

Defines texture, weight, durability, and overall performance.

Common frame materials include TR90, PC, acetate, Ultem, and metals such as stainless steel and titanium, each affecting flexibility, comfort, strength, color expression, and regulatory compliance (e.g. REACH).