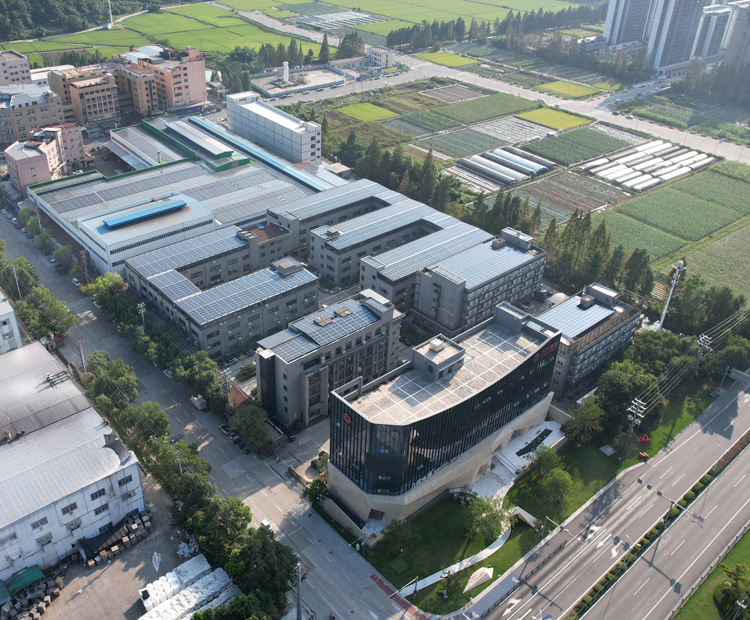

2,000 + m²

Modern Production Space

By combining advanced technology, refined craftsmanship, and strict quality control, we create optical frames that deliver consistent performance, comfort, and visual identity.From precision machining to seamless assembly, every frame is produced in accordance with international standards and your brand specifications.

Modern Production Space

Skilled Technicians

High-End Frames per Month

International Leading Brands Collaborated

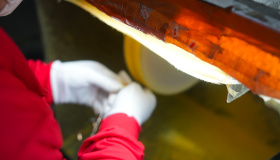

Our premium cellulose acetate offers exceptional flexibility, skin-friendly comfort, and deep color luster. Through our optimized aging and hot-pressing protocols, we eliminate internal stress to prevent warping, ensuring a high-end finish that lasts.

Rich, Natural Luster & Texture

Precision Hot-Bending for Ergonomic Fit

Multi-layered Composites & Gradient Textures

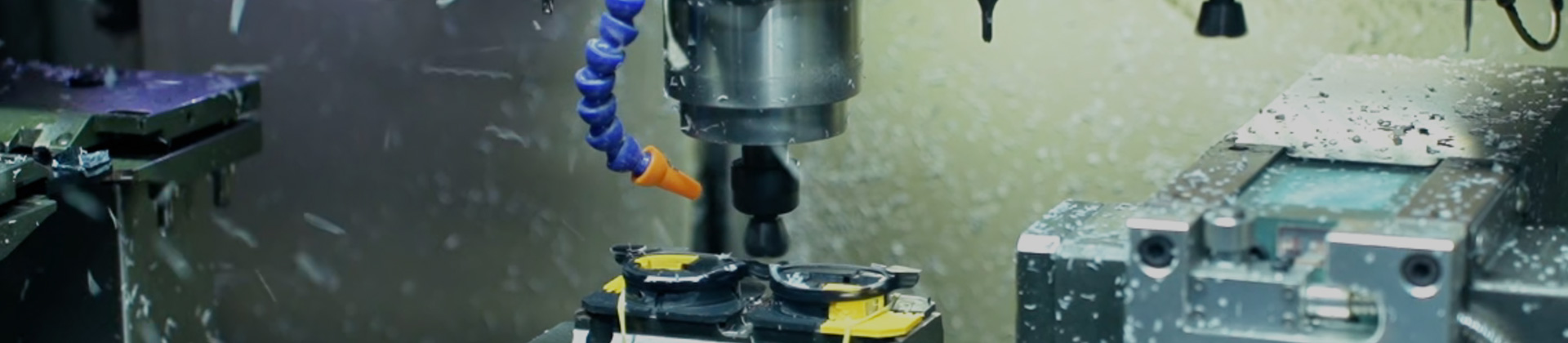

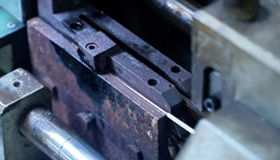

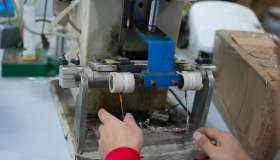

Micron-level automated cutting provides the perfect geometric foundation and high consistency for batch production.

7-day slow baking increases hardness by 10–15% and reduces deformation to<0.3% for maximum frame stability.

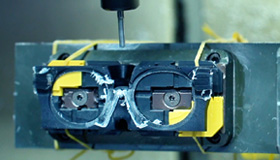

Secondary precision machining of contours and edges ensures every curve matches the original design specifications.

Specialized heating and curving ensure the frame base curve perfectly matches the lens for a secure, tension-free fit.

Manual adjustment of bridge angles and temple curves to ensure superior comfort and pressure-free wearing.

Extended tumbling with organic media smooths every edge, creating a silky-soft touch even on complex shapes.

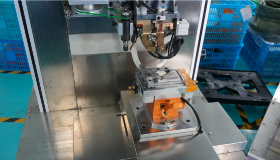

Automated drilling and precision pinning ensure smooth hinge movement and long-term structural integrity.

High-resolution laser and mechanical engraving for intricate patterns and brand logos with extreme clarity.

Multiple stages of mechanical and artisanal hand-buffing achieve a mirror-like gloss and premium tactile feel.

Multi-frequency ultrasonic baths remove all micro-residues, ensuring a pristine surface for final inspection.

Automated grooving with a tolerance of ±0.1mm guarantees a seamless and secure fit for all lens types.

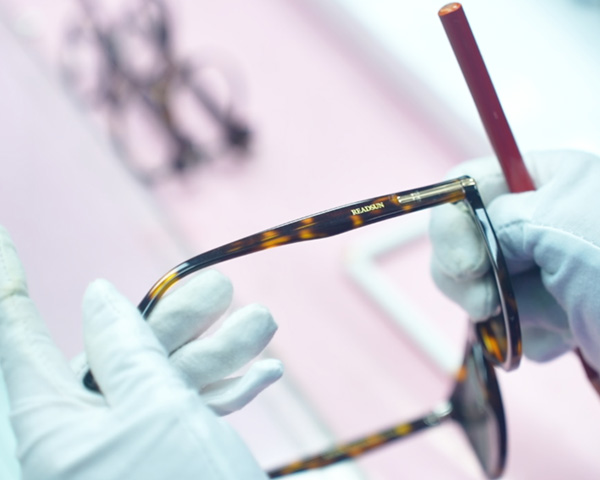

Final rigorous testing according to ISO 12870 standards to ensure zero-defect delivery and global compliance.

Watch our comprehensive manufacturing journey. This video showcases the synergy between advanced CNC technology and traditional hand-craftsmanship that defines every Readsun acetate frame.

Utilizing Swiss-imported TR90 and medical-grade polymers, our injection process achieves ultra-lightweight durability and memory-flexibility. We specialize in complex, high-strength frames that maintain their shape under extreme conditions while offering unparalleled skin-friendly comfort.

Proprietary Material Blending for Uniform Performance

Ultra-Tight Tolerance (±0.05mm) for Complex Shapes

Advanced Dual-Color & Gradient In-Mold Integration

Exclusive drying and blending of TR90/PC/PEI resins ensure uniform physical properties, eliminating structural defects and warping.

Fully automated injection molding with a strict ±0.05mm tolerance, supporting ultra-thin, wide, or highly complex frame geometries.

Advanced vibratory grinding smooths out parting lines and sharp edges, ensuring a perfectly rounded and aesthetic finish.

Ultrasonic and high-pressure air cleaning ensures a flawless, debris-free surface for a premium tactile experience.

Precision setting for dual-color or gradient designs, ensuring no bubbles or misalignment for an upscale aesthetic.

A combination of CNC and manual trimming ensures clean, sharp edges and burr-free surfaces with consistent dimensions.

Mechanical and manual buffing achieves either a high-gloss mirror effect or a sophisticated matte finish.

Superior adhesion and vibrant color application tailored to client specifications, providing a durable and beautiful finish.

Automated screw driving with torque control prevents loosening and ensures smooth, durable hinge operation.

High-resolution laser engraving or pad printing provides permanent, clear markings without damaging the surface.

Final manual frame shaping ensures perfect alignment, smooth hinge movement, and an ergonomic fit for maximum comfort.

Comprehensive inspection of dimensions, flexibility, color, and finish; we only ship 100% qualified frames.

Our metal eyewear manufacturing combines aerospace-grade laser welding with meticulous hand-finishing. We specialize in working with premium stainless steel, Monel, and Titanium, ensuring every frame is lightweight, hypoallergenic, and structurally superior for long-term durability.

Zero-Visible Laser Welding with High Tensile Strength

Hinge Endurance Tested for Over 10,000 Cycles

Sub-0.1mm Tolerance for Perfect Symmetry

High-precision laser welding ensures the bridge is symmetrical and robust, passing rigorous tensile tests even for complex designs.

Automated micro-welding ensures maximum hinge durability, guaranteed to pass 10,000+ open-and-close cycle tests.

Precision annealing reduces material stress, allowing for perfect curvature without micro-cracks while ensuring easy temple adjustment.

Propelling a<0.1mm tolerance, our specialized laser technology creates seamless joins with invisible weld seams for superior aesthetics.

A combination of mechanical buffing and artisanal hand-polishing achieves a flawlessly smooth, high-luster mirror finish.

Advanced vibratory tumbling enhances the tactile feel and visual depth, ensuring rounded edges even on the most intricate shapes.

Exact cutting ensures the frame perfectly accommodates lenses, reducing assembly errors and providing standard templates for future glazing.

CNC machining ensures a ±0.1mm accuracy for temple tips, maximizing symmetry and ergonomic comfort for the wearer.

Customized bending processes ensure a consistent angle across entire batches, perfectly aligned with human facial ergonomics.

Automated screw insertion with precise torque control prevents loosening; nylon-coated screws are used for smoother hinge operation.

High-resolution laser engraving ensures clear, permanent branding and information without compromising the metal surface.

Exhaustive testing for dimensions, structure, and functionality; only 100% defect-free frames are approved for international shipping.

Full-process inspection covering materials, structure, comfort, and durability

Each batch complies with CE / FDA / ISO9001 standards

Digital quality records ensure full traceability and issue tracking

Learn more

Utilizing bio-based materials, biodegradable boards, and RPET children's optical frames

Solder-free process, low-VOC coatings

Supporting customer environmental requirements and meeting global green standards